Resin floors have become increasingly popular in various settings due to their exceptional properties and versatility. In this comprehensive guide, we will delve into the world of resin floors, exploring what they are, how they are made, the different types available, their benefits, applications across diverse industries, and the installation process.

Whether you're a homeowner, facility manager, architect, or contractor, understanding the intricacies of resin floors is essential for making informed decisions about flooring options. Join us as we uncover the fascinating realm of resin floors, from their composition to their practical applications.

Table of Contents

Resin floors are a type of flooring system known for their seamless and durable properties, commonly made from epoxy or polyurethane resins.

These floors are highly sought after due to their seamless nature, creating a smooth and continuous surface that is both aesthetically pleasing and practical. Resin floors are exceptionally durable, standing up to heavy foot traffic and impact without showing signs of wear. Their resistance to chemicals makes them an ideal choice for industrial and commercial settings where spills and exposure to harsh substances are common. Their easy maintenance and cleaning requirements make them a convenient and cost-effective flooring solution for various applications.

The production process of resin floors involves the installation of a specialized material that undergoes surface treatment, coating, and finishing to achieve its characteristic properties.

During the installation stage, the resin material is carefully mixed and poured onto the prepared subfloor, forming a seamless and durable surface. The surface treatment may involve diamond grinding or shot blasting to enhance adhesion and smoothness. Subsequently, the coating process applies layers of epoxy or polyurethane resin, which are then cured to form a resilient and attractive floor. The finishing touches, such as sealants or topcoats, provide the desired aesthetic and protective qualities.

There are various types of resin floors, including epoxy, polyurethane, acrylic, and Methyl Methacrylate (MMA) resin floors, each catering to specific requirements in interior design, construction, and various residential and commercial settings.

Epoxy resin floors are known for their exceptional durability and chemical resistance, making them ideal for high-traffic areas such as industrial spaces and warehouses.

Polyurethane resin floors are flexible and offer seamless, non-porous surfaces, making them suitable for healthcare facilities and food processing areas.

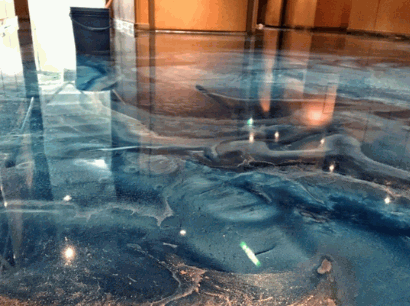

Acrylic resin floors are popular for decorative purposes, thanks to their versatility in creating colorful, decorative finishes, often used in retail and entertainment venues.

MMA resin floors are valued for their fast curing time, making them suitable for quick installation in commercial spaces with minimal downtime.

Epoxy resin floors offer a range of advantages and disadvantages, providing a versatile surface material with customizable aesthetics and suitability for refurbishment projects.

They have gained popularity for their durability, resistance to chemicals, and high-traffic areas, making them ideal for commercial spaces. Epoxy resin floors can be tailored to various color schemes, patterns, and finishes, providing an extensive range of design options for both contemporary and traditional settings.

Their installation requires meticulous preparation and skilled application, and they may not be suitable for areas prone to high levels of moisture, as they are not inherently resistant to water.

Polyurethane resin floors are renowned for their high performance, offering superior protection, anti-slip properties, custom designs, and sustainable features.

These exceptional floors provide an effective barrier against wear and tear, chemicals, and heavy foot traffic, making them ideal for industrial, commercial, and residential settings. Their anti-slip properties ensure safety in high-traffic areas, preventing accidents and injuries. Thanks to their customizable designs, these floors can be tailored to match any aesthetic or branding requirements, allowing for endless creative possibilities.

Their sustainable attributes, such as low VOC emissions and long-term durability, contribute to a reduced environmental impact, making them a responsible choice for eco-conscious projects.

Acrylic resin floors are known for their decorative and modern appeal, offering versatile aesthetics, design flexibility, and long-lasting performance.

Their seamless finish and ability to be customized with various colors, patterns, and textures make them a popular choice for modern interior design. With their durability and low maintenance nature, acrylic resin floors are favored for both residential and commercial spaces, bringing a sleek and polished look to any environment.

The fluid, glossy surface also reflects light beautifully, enhancing the overall visual impact of the space. These floors seamlessly merge durability with contemporary design, making them a desirable option for the modern discerning homeowner or business owner.

Methyl Methacrylate (MMA) resin floors are distinguished by their fast-curing properties, requiring specific surface preparation, strong adhesion, and variable thickness for installation.

This unique flooring option sets itself apart by its ability to cure rapidly, allowing for faster installation and minimal downtime. The surface preparation for MMA resin floors is crucial, as it ensures proper adhesion and long-term performance. These floors exhibit exceptional adhesion strength, making them suitable for high-traffic areas and demanding industrial environments. The variable thickness of MMA resin floors provides flexibility in meeting specific project requirements, whether it's a thin protective coating or a thicker seamless flooring solution.

Resin floors offer numerous benefits, including their versatile applications, advantageous properties, and suitability for commercial buildings.

They are highly customizable and available in a wide range of colors and finishes to complement various design aesthetics. Their seamless, non-porous surface makes them easy to clean and maintain, ideal for high-traffic areas in commercial settings.

Resin floors are durable and resistant to chemicals and heavy impacts, ensuring long-lasting performance in industrial facilities, warehouses, and retail spaces. Their ability to be installed over existing substrates also minimizes downtime during renovations, making them a cost-effective choice for commercial property owners.

The durability of resin floors is evidenced by their seamless finish and suitability for high-traffic areas, ensuring long-lasting performance in various settings.

This type of flooring is specifically designed to withstand heavy foot traffic, making it an ideal choice for commercial spaces, industrial facilities, and public venues. Its resistance to wear and tear, along with its seamless nature, not only offers an aesthetically pleasing appearance but also requires minimal maintenance, reducing the need for frequent repairs or replacements. This makes resin floors a cost-effective solution for high-traffic environments, providing a durable and reliable flooring option.

Resin floors demonstrate exceptional resistance to chemicals and stains, making them ideal for industrial applications and chemical processing plants.

Their ability to withstand strong acids, alkalis, solvents, and other harsh substances is crucial in industrial settings where chemical spills and exposure are common. The seamless nature of resin floors also prevents any lingering stains, ensuring a hygienic and low-maintenance environment. These qualities make resin floors a reliable choice for:

where chemical resistance and durability are paramount.

The easy maintenance of resin floors, characterized by their low-maintenance and hygienic properties, makes them a practical choice for various settings.

They are highly resistant to stains, chemicals, and scratches, eliminating the need for extensive upkeep. Their seamless surface discourages the accumulation of dirt and bacteria, ensuring a hygienic environment.

Resin floors can be easily cleaned with simple mopping or gentle scrubbing, saving time and effort. This makes them ideal for commercial spaces, healthcare facilities, and even residential areas where cleanliness and minimal maintenance are essential.

The customizable design options of resin floors extend to a wide range of choices, including color options, textures, designs, and patterns, catering to diverse aesthetic preferences.

Encompassing an array of colors, from subtle neutrals to vibrant hues, resin floors offer the chance to create personalized spaces that express individual style. Different textures, such as polished or matte finishes, further enhance the customizable possibilities. The design flexibility of resin floors allows for seamless integration of patterns, such as geometric shapes, organic motifs, or even customized logos, enabling endless creative combinations for both residential and commercial spaces.

Resin floors find extensive applications in renovation projects, serving as an alternative surface treatment for both commercial buildings and residential spaces, including kitchens and bathrooms.

Their versatility and durability make resin floors an excellent choice for modernizing and enhancing existing floors, providing a seamless, easy-to-maintain surface. In commercial settings, such as restaurants, retail stores, and offices, resin floors offer a hygienic and stylish solution, while in residential spaces, they bring a contemporary and practical touch.

Their range of finishes and colors allows for customization, making them suitable for diverse design preferences in various settings.

Resin floors are prominently utilized in industrial and commercial spaces due to their high performance, suitability for high-traffic areas, and exceptional chemical resistance.

These durable and dependable flooring solutions are ideal for areas with heavy footfall and machinery movement, such as manufacturing plants, warehouses, and food processing facilities. Their seamless application and resistance to harsh chemicals make them well-suited for spaces where spillages and exposure to various substances are common occurrences.

Resin floors offer a protective shield against wear and tear, providing long-lasting performance and reducing the need for frequent maintenance, which is crucial in high-traffic industrial settings.

Resin floors offer a practical flooring solution for residential settings, including homes, kitchens, bathrooms, and living spaces, enhancing both aesthetics and functionality.

They provide a seamless and easy-to-maintain surface that can withstand heavy foot traffic, spills, and daily wear and tear, making them ideal for busy households. With a range of colors and finishes available, resin floors can be customized to suit various interior styles, from modern to minimalist, adding a sleek and contemporary touch to any residential space.

Their durable nature makes them perfect for high-moisture areas like bathrooms and kitchens, offering resistance to water and stains. Resin floors contribute to a cohesive and visually appealing design scheme, creating a sophisticated and inviting atmosphere within the home.

The installation of resin floors in healthcare facilities is driven by their hygienic properties, low maintenance, and seamless finish, contributing to a clean and safe environment.

These specialized floors offer a non-porous surface that prevents the growth of bacteria, making them ideal for healthcare settings where infection control is paramount. The seamless finish reduces the risk of trip hazards and facilitates easy cleaning, promoting a hygienic environment.

With their low maintenance requirements, resin floors save time and resources, allowing healthcare staff to focus on patient care while ensuring the highest standards of cleanliness and safety.

Uncover more: Is Resin Flooring Suitable For Bathrooms

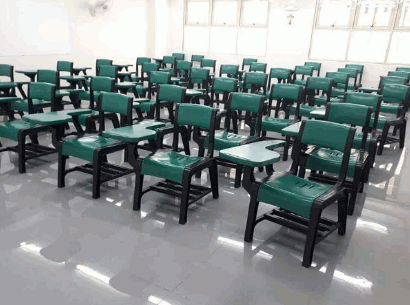

Educational institutions benefit from the installation of resin floors, offering durability and low maintenance in high-traffic areas, ensuring long-term functionality and aesthetics.

These highly durable floors are particularly well-suited to withstand the constant movement of students and staff, making them an ideal choice for schools, colleges, and universities. In addition, resin floors are resistant to stains, chemicals, and general wear and tear, ensuring a long-lasting, pristine appearance that contributes to a safe and hygienic environment for learning and activities.

Their seamless, easy-to-clean surface promotes healthy indoor air quality, reducing the spread of allergens and bacteria that can often be prevalent in educational settings.

The installation of resin floors requires professional application, skilled labor, and attention to factors such as curing time, substrate preparation, and adhesion to ensure a successful outcome.

Expertise in substrate preparation is crucial as it determines the long-term durability of the resin floor. Skilled labor is essential in maintaining a consistent mixture and application process. The curing time must be meticulously monitored to achieve optimal strength and durability. Adherence to manufacturer guidelines for adhesion and compatibility with the substrate is also paramount. All these considerations highlight the necessity of entrusting the installation of resin floors to experienced professionals.

Surface preparation is a critical phase in the installation of resin floors, requiring specialist application, proper substrate assessment, and strong adhesion for optimal performance.

It ensures that the substrate is free from contaminants, such as dirt, grease, and oil, which can compromise the adhesion of the resin. Specialist application techniques, such as shot blasting or diamond grinding, are essential for creating a roughened surface that promotes bonding.

A thorough substrate assessment helps identify any imperfections that could negatively impact the installation. Ultimately, strong adhesion is vital to prevent delamination and ensure the longevity of the resin floor, making surface preparation a crucial step in achieving a durable and aesthetically pleasing result.

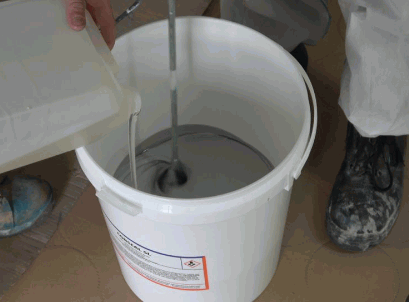

The mixing and application of resin during installation require professional expertise, precise material handling, and skilled labor to ensure a flawless and long-lasting finish.

It is essential for professionals to meticulously measure and mix the resin, ensuring the correct ratio for optimal performance. The proper application technique is crucial, as it requires a steady hand and an understanding of the material's behavior. Skilled labor is necessary to manage any unexpected challenges that may arise during the process, such as temperature variations or uneven surfaces. Professional installers are trained to handle these intricacies, ensuring that the resin is applied accurately and efficiently for a durable and polished result.

The curing and finishing stages of resin floor installation determine the overall quality, requiring attention to curing time, finishing techniques, and future maintenance and repair considerations.

Proper curing time is essential to ensure the resin material fully hardens and bonds to the substrate, leading to a durable and long-lasting floor. The finishing methods, such as polishing or adding a topcoat, not only enhance the aesthetic appeal but also contribute to the floor's protective and functional properties.

When it comes to maintenance and repair, understanding the curing and finishing processes is crucial for implementing effective upkeep and addressing any issues that may arise over time, ensuring the longevity and performance of the resin floor.